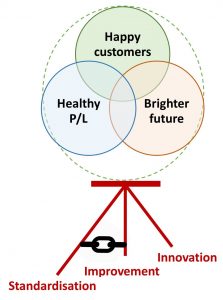

The SII Model:

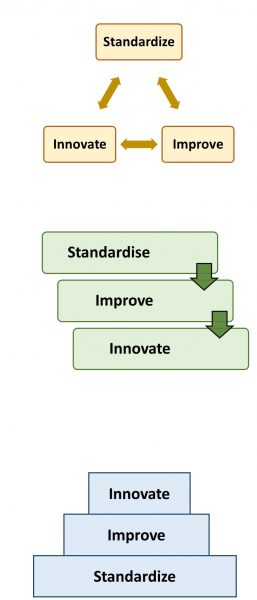

In the last few years I have heard speeches of several business leaders on ‘Innovation’. Most emphasize the importance of culture for innovation. Some, especially those who have an influence of Japan, use a chart to show the interconnection between Standardization, Improvement and Innovation.

I completely agree that these three elements are important for all organizations, but I have a problem with the way they are managed. I disagree with all the three ways in which these three elements are depicted in the figure.

People call these three elements as SII and explain it as if it is a serial process. Many business managers lament that they are still in standardization and Improvement phase and are hence helpless to initiate any work on Innovation.

In my view all three elements are equally important. Organizations need to actively pursue just a few innovations at any given time. Improvements are far more in numbers and standardization must be pervasive. If I were to draw an analogy, Innovations are like stones, improvements are like small pebbles and standardization is like sand all put together in an empty flask/jar. If we need all three but start with filling sand, very soon there will be no space left for stones (Innovation). Pebbles (improvements), though, could be pushed through the sand with some brute force – we all see it happening all the time.

If we delve deeper, we will understand that SII would have started as a serial process (one after the other). Most Companies (at least in India), in the last several decades, have been established based on a successful product and a business model that was innovated in the western world. The market in India has always been big and hence it was important to focus on standardization and consistency in products and processes to get quicker returns from the investment. When companies focus on standardization (of processes and products) they make good progress in the beginning and it reflects in their key metrics. The measures for standardization could be deviations or variance (also measured through control charts and ‘sigma’ levels are a few of them). This system of calculating deviations or defects was found to be very useful as it triggered managers to reduce the variations to improve performance. This gave birth to many improvement initiatives like six-sigma. This journey of improvement was energizing for almost all successful managers and they continued to excel in the race.

Should we make Standardization and Improvement pervasive?

Is it necessary for all processes to be at 6 sigma level and then start thinking about innovation? NO!

Unfortunately, I see this happening. Do we need the lunch break to be a six-sigma process? Do we need the meetings to follow a six-sigma process? Organizations can have processes at two-sigma level also. On the other hand, there could be processes that need to be better than six-sigma. Let’s take example of the airlines industry. The aircraft landing system would be better than six-sigma. The on-time performance would be typically in the range of 3-4 sigma. The baggage handling system would have a sigma level of four to five. Are all airlines making losses and is this low level of sigma the reason for their losses? What is the reason for some airlines making profit? Is it because of their laser sharp focus on controlling variations and defects or because of a new business models and a few interesting service innovations?

Organizations perhaps never wanted all their processes to be at six-sigma. Unfortunately, the fierce drive for standardization and improvement program drove everyone crazy. Functions and processes which were not necessarily intended for six-sigma felt left out once the rewards, recognition and performance appraisal were tied to continuous improvement.

No time for Innovation!

So where is the problem in the above? The problem is in considering SII as a serial process. There will never be a time when a company would say that we have done enough (finished) of Standardization and Improvements and hence now let us focus on Innovation. Standardization and Improvements have no limits. One can always aspire for lower defect levels and higher levels of sigma which may not always be beneficial as people may end up spending lots of energy in areas where improvements are not necessary (considering law of diminishing returns and cost-benefit analysis).

The results from improvements are immediately visible and this makes it a virtuous circle – Business leaders and management demand even more improvements. This results in simultaneous rotation of two contradictory circles – virtuous and vicious. The improvements fuel more standardization and more improvements but unfortunately makes it difficult for innovation to begin. This is similar to our example of stones, pebbles and sand – As companies immerse themselves in improvement triggered by standardization, there is no (mental, cultural) space left for Innovation. The culture where all three co-exist is very difficult to create if we make it a serial process.

In the first 10-12 years of my career, I was a practitioner of standardization and improvement. I know how addictive and never ending the journey is. For the last 10 years I have become a practitioner of Innovation. The shouts, cries and complaints of the customers and market even today demand a lot of process improvements and standardization. On the other hand, one would never ever hear a cry/demand from customers that would demand innovations. ‘Lack of standardization’ is usually the reason for customer complaints, ‘lack of improvement’ is the reasons for customer dissatisfaction and ‘lack of innovation’ could be the reason for not having customers!

I referred to the book of Dr Shoji Shiba and Dr David Walden – ‘Breakthrough Management’. The authors write in this book,

Thus, many years ago it was sufficient to introduce a technology and then do control management for many years. A little more recently, say as recently as the mid-1980s, a company could introduce a new technology, do control management, and then add management of incremental improvement to remain competitive. A firm could alternate back and forth between incremental improvement and control for years until eventually it needed to make a new breakthrough to stay in business.”

They continue,

Today, management often must be done in a new way. A business starts with a breakthrough producing the new product exactly as developed and getting it under control. From there one improves the product using the methods of incremental improvement, getting each change under control; but, surprisingly so

on, it becomes necessary to jump to the next breakthrough.”

This diagram from his book clearly indicates that the three are not a serial process.

Prof Shiba, in the same book suggests, “In paintings relating to Buddhism, three eyes are sometimes shown. These are the eye of the past, the eye of the present, and the eye of wisdom. The three types of management, which today’s CEOs must simultaneously be concerned with, can be illustrated as the three eyes in Buddhism, as shown in the Figure below. That is, the CEO needs an eye to monitor management for c ontrol, or else the company will not meet the minimum contract between the company and society. The CEO needs an eye to monitor management for incremental improvement, or else the company will not keep up with changing customer requirements. And the CEO needs the wisdom to see the path to future breakthrough, or else the company will have no tomorrow”

ontrol, or else the company will not meet the minimum contract between the company and society. The CEO needs an eye to monitor management for incremental improvement, or else the company will not keep up with changing customer requirements. And the CEO needs the wisdom to see the path to future breakthrough, or else the company will have no tomorrow”

I believe that this analogy and the picture also fails to adequately communicates the equal importance of three subjects.

The Tripod

For me, the three subjects are like three legs of a tripod. In absence of any one leg the tripod is completely unstable. Interestingly, Tripod manages stability even if there is a difference in the length of three legs. In my previous post I shared that companies should change their PDCA method to PCDCA, which will become a common tool for Improvements and Innovations.

Established companies should identify a few large stones and then put the small pebbles and sand. I would therefore suggest that we need to have a system that ensures a few large stones (Innovations) in the organization. All those processes that have a huge bearing on costs, customer complaints and engagement should be surrounded by smaller pebbles (Improvements) and sand (Standardization) but only up to a point until these processes achieve a certain expected level and fetch returns that commensurate the efforts. The law of diminishing returns applies to improvements – there will always be a point when the opportunity cost of not investing on innovations exceeds the returns from improvements. When company reaches this point, it is the time when they rejig the flask (similar to Kaleidoscope) and ensure there are a few large stones in it. Kaleidoscope is a cylinder (tube) with colored objects such as beads, or pebbles and bits of glass. It would typically have three mirrors to reflect the patterns made by the combination of beads, pebbles and glass. Once the tube is rotated, a new random pattern emerges for the viewer. In a similar manner, we in our organization should have the presence of all three (Innovation, Improvement, Standardization) elements. The intensity and application areas of these elements could vary depending upon the need of the organization. Who would rotate the Kaleidoscope? This is one role of the several roles of Chief Innovation Officer!

References: