In the last few months, I have expressed my views on the challenges that shroud most established companies to innovate. Several similar challenges and related solutions have been detailed in my book ‘Making Innovations Happen’. During my presentations to the executives, new issues have been raised by the participants, some of which are complex. In this post, I have attempted to explain my response to one such issue – ‘We have been following PDCA. Doesn’t it enable innovations and take care of the challenges that established companies face? If not, why?’

Popularity of PDCA

It would be good to know the perception that has been built on this subject of PDCA. The perceptions on management subjects like PDCA get built majorly through published literature. Hence, I started by googling on various words and here are the results:

- PDCA: 51,60,000

- PDCA and continuous improvement: 3,35,000

- PDCA and innovation: 2,65,000

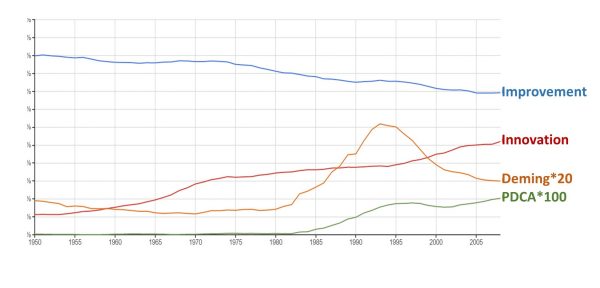

The above data doesn’t provide any useful information to us and hence I performed Ngram search on these words (Innovation, Improvement, PDCA and added Deming too) to check the number of books written on these subjects. Below is the trend. The ‘Deming’ line shows an interesting bump in the decade of 1990-2000, which perhaps had some effect on PDCA curve as well. Interestingly the slope of the curve for innovation increases after the peak of Deming.

Armed with this information, I dived deeper on these subjects. The tone of top few google results for ‘PDCA and continuous Improvement’ was dominantly to explain PDCA and its role in achieving continuous improvement. There were a few case studies and a few offerings of consultants. Interestingly there was one that explained the difference between PDCA and 6-sigma. On the other hand, the top few results for ‘PDCA and Innovation’ were surprising and unfortunately misleading. They were thrown by google simply because the authors had chosen ‘innovation’ as one of the tag words while uploading their documents although the contents had nothing about innovation. A few documents were on the debate between PDCA, continuous improvement and innovation.

In the 3rd stage, I used the ‘carrot search’ (http://search.carrot2.org/stable/search) which analysis the top few results on the web and throws the results after creating themes. The results of four different searches are shown below with the search keyword in the center and the themes around each one of them. None of these four analysis indicated any explicit connection with Innovation.

Understanding PDCA

We know that W. Edwards Deming, in the 1950’s, proposed that business processes should be analyzed and measured to identify sources of variations that cause products to deviate from customer requirements. As a teacher, Deming created a (rather oversimplified) diagram to illustrate this continuous process, commonly known as the PDCA cycle. Deming recommended that business processes be placed in a continuous feedback loop so that managers can identify and change the parts of the process that need improvements. I strongly believe that Deming did not limit the PDCA to improvement but perhaps because the need of the hour at that time for his target companies was to focus on continuous improvement and improve the quality standards of manufacturing companies, the bond between PDCA and improvement became stronger. It got reinforced with the publication of successful case studies and phenomenal results obtained by most Japanese companies. I don’t know if people tried to use PDCA for innovations at that time but unfortunately, in absence of data I would conclude that they either they didn’t try or failed to get noteworthy results. No wonder in the carrot diagram above, the themes in ‘PDCA and innovation’ have no reflection of any aspect of innovation.

Let us now look at PDCA with some more details along with the tools that are used to rotate the PDCA cycle:

Plan: Identify the problem and analyze data/information to find the root cause. Tools like process mapping/flow chart, ‘fishbone’ diagram (cause and effect diagrams), Pareto analysis, 5 whys, frequency charts etc. are helpful to find the root cause(s) of the problem. Develop hypotheses about what the issues may be and decide which one to test. Explore different possible solutions, develop and test a potential solution. This could involve experimental design, conflict resolution or other approaches.

Do: Communicate the implementation plan to all concerned and try the solution as a Pilot as per the plan. Gather test data, Review the progress and repeat the test if needed.

Check: During the check phase, the data and results gathered from the Do phase are evaluated. Data is compared with the expected outcomes to see if there were any changes. If the result achieved is not as per plan, it becomes a deviation (a problem again) for which we need to go back to either go back to “Do” or “Plan”. If the test shows good results, then we move to the next phase of ‘Act’.

Act: If the check phase shows that the new solution is an improvement to the prior standard (baseline), then the new solution becomes the new standard (baseline) for how the organization should act going forward. Instead, if the check phase shows no or less than expected improvement, then the existing standard (baseline) will remain in place. We need to find out why the new solution did not give desired result. Process-monitoring and control tools are recommended for this last step for the standardization and sustenance of the achieved result.

Having studied and analyzed the perception and facts about PDCA, I will now share my views and explain the reasons for this perception about weak connection between PDCA and innovation.

As mentioned earlier, PDCA started at the time when focus in companies was to make continuous improvement to manufacture better quality products. It was very successful and as a result, it was used as a program to create a culture of continuous improvement. Successful case studies and conferences reinforced this adoption of PDCA. The question is: “Does PDCA trigger, enable and support innovations too?”

We all want to move PDCA cycle fast…

Getting entrenched in PDCA with the prime objective of driving continuous improvement will create a culture that may not be able to deliver innovations. When I checked with some of the experts of PDCA, I came to know that typical PDCA cycles are of a few days or few weeks. Only in some complex cases which needs in-depth data collection and analysis, the cycle could last 3-6 months. The ‘C’ stage of PDCA checks if the outcome was delivered as per expectations. If it didn’t deliver, the focus is mostly on how well the plan was made and executed. It is extremely rare that the adequacy of the Plan itself is questioned.

But innovations typically have longer ‘Do’

Let me highlight a reason why PDCA approach is not able to drive innovations. In most innovation projects, the time gap between P and C is expected to be large (means that ‘D’ is comparatively longer for innovation projects). It could be months and years and surely it is much more that what one would expect for continuous improvement projects. This large time gap has a negative effect on ‘D’ as managers prioritize those projects where the ‘D’ is comparatively shorter, which would contribute in making them effective in the eyes of their superiors and fetch better performance appraisals.

Problem with ‘Plan’

Now let me come to the second problem, which is associated with ‘Plan’. In most cases, the P for continuous improvement projects need linear thinking. It is perhaps for this reason that TQM/Deming assessment advocates use of stretch targets. ‘Plan’ is most crucial for innovation projects and I believe that we need to be unreasonable and non-linear while making ‘Plan’ for innovations. The content of ‘P’, which is the first stage of PDCA, by and large decides if the outcome of the project would result in an innovation or not. I believe that while continuous improvement on a regular basis is necessary for any company to improve throughput and profits, Innovation is equally crucial – although the frequency of innovations would be less than that of continuous improvement. To draw an analogy from the game of cricket, (and would be true in all other sports), taking singles and twos are equally or even more important than hitting fours and sixes (Read portfolio of Indian cricketer MS Dhoni).

Recommendations

I therefore recommend the following two changes in PDCA to drive innovations better:

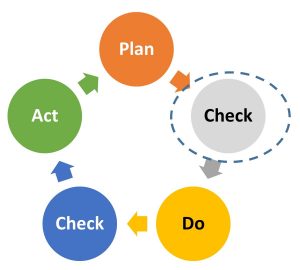

PDCA to PCDCA:

‘Check’ should not only check the outcomes of ‘Do’ to decide if we should move to ‘Act’ or not, it should also inform if the ‘Plan’ was expected to trigger/demand innovations. But verifying the outcomes of ‘Plan’ after ‘Do’ is too late and perhaps a wasteful exercise. I therefore recommend a small change in PDCA – We need to introduce a ‘C’ after ‘P’ to check if the plan is audacious (non-linear or non-obvious) enough to demand and deliver innovations. By doing this, the process and tools used for making the ‘Plan’ would gradually get enriched. In other words, I recommend that before embarking on ‘Do’, the project teams should be able to set the expectations on the outcomes of ‘Do’ in terms of innovation. If they think that the outcome will solve the problem but is unlikely to be innovative, it has two choices – continue with the ‘Plan’, followed by ‘Do’ and deliver the improvement OR revisit the Plan and modify it until the Plan is capable to deliver an innovation. The Plan depends on the combination of problem definition and the solution chosen by the team. The Plan clearly indicates if the result would be an innovation or not. Let me give an example of how the problem statement could have major impact on the Plan is: The problem statement of ‘cutting the grass efficiently to a height of 1 inch’ would result in very different Plan as compared to the problem of ‘Keeping the grass at the height of 1 inch”. The former will focus on improving the effectiveness of cutting, the later may trigger a method to stop the growth of grass. When, how and who evaluates this aspect of ‘Plan’? Adding a “Check’ after ‘Plan’ would set the right expectation from the project. Look at the three examples of problem statements – train station , Hotel selection and Potholes, which I think are not likely to get captured using PDCA process.

Sustain focus and interest on Long duration ‘D’

Similarly, I feel that ‘D’ of PCDCAinnovation needs some more tools that will ensure that managers are able (and allowed) to focus and invest (D) on innovation projects that are of longer duration. We might need to add more tools related to Risk Assessment and mitigation, Designing new business models, Open Innovation etc. But I am a strong believer that while tools do help and bring efficiency in accomplishing the desired job, it is the behavior which is most critical. The behavior and body language of leaders and superiors decide if one would like to begin a journey of innovation or not. We need a method that encourages all managers (top to bottom) to start the longer-term journey of ‘D’ and sustain it to deliver innovations. I have proposed one such method in one of my later posts.

While I have made a strong recommendation to modify PDCA to PCDCA it doesn’t mean that I consider innovation better than improvement. I firmly believe that Innovation, Improvement and Standardization need to co-exist in any organize.

References:

- http://www.innovation-portal.info/resources/deming-wheel-pdca-cycle/

- http://gembapantarei.com/2012/05/how_is_pdca_inimical_to_innovation.html

- http://asq.org/learn-about-quality/project-planning-tools/overview/pdca-cycle.html

- https://balancedscorecard.org/Resources/Articles-White-Papers/The-Deming-Cycle

- http://www.brighthubpm.com/methods-strategies/75926-exploring-the-uses-of-plan-do-check-act-pdca-cycles/

- https://hbr.org/2012/05/its-time-to-rethink-continuous.html?utm_source=pulsenews&utm_medium=referral&utm_campaign=Feed%253A+harvardbusiness+%2528HBR.org%2529